Another topic of attention is the so called support while printing.

Classic plastic based kits like: Tamya, Airfix and similar, are created from a mould consisting of multple tight fitting elements that work under high presure and temperature to drive the plasic into the mold. Usually only the additional attachments to a frame need to be removed, to process the parts.

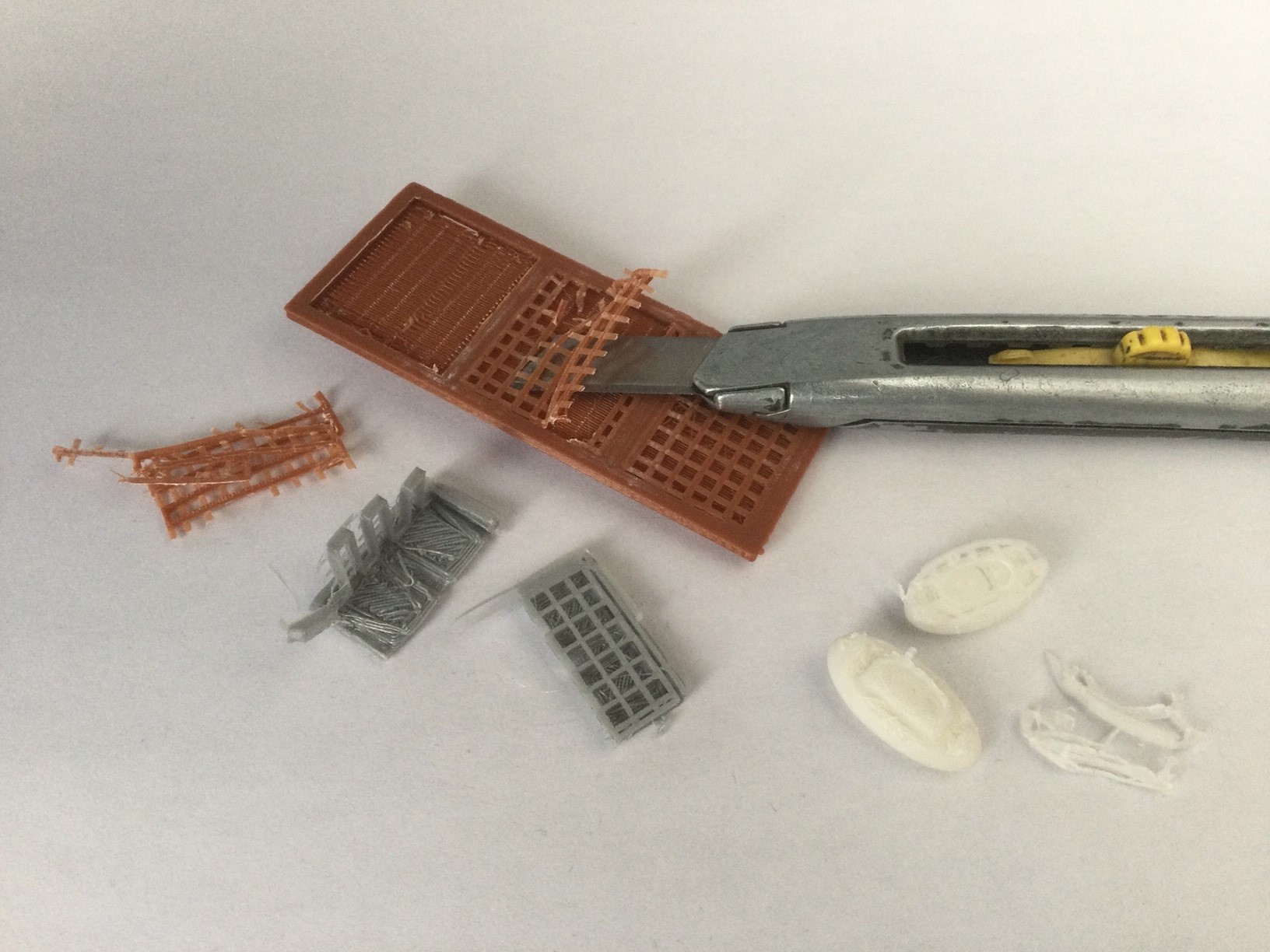

For 3D printing, this doesn't apply. Every printed part needs a connecting to the build-plate, from where every layer is printed upon the earlier printed layer. As printing in the thin air is not possible, some parts may need some overhead printed to have some kind of temporarly attachment to this build plate. See the example below.

Of course, prior to mounting these parts into your model, this temporarlily overhead material [the support] needs to be removed. Sometimes you can simply tear it off, where in more delicate printed parts a knife is more convenient.

Reacties